Safe Manual Handling: A Comprehensive Guide

Manual handling is a common activity in many workplaces, but it can also pose significant risks to workers’ health and safety. According to the Health and Safety Executive (HSE), manual handling causes over a third of all workplace injuries, including musculoskeletal disorders (MSDs), such as back pain, sprains, strains, and hernias. Manual handling also accounts for a large proportion of work-related ill health, absenteeism, and reduced productivity 2 .

In this article, we will provide an in-depth guide on what manual handling is, why it is important, what are the hazards and risks associated with it, and how to prevent and reduce them. We will also cover the legal requirements and best practices for manual handling, as well as the training and assessment methods that can help improve workers’ competence and performance. By following this guide, you will be able to implement effective manual handling policies and procedures in your organization, and ensure the health and safety of your workers and yourself.

Table of Contents

What is Manual Handling?

- Lifting and lowering: This involves raising or lowering an object from one level to another, such as from the floor to a shelf, or from a conveyor belt to a pallet.

- Carrying: This involves holding or supporting an object while moving from one place to another, such as from a warehouse to a truck, or from a storeroom to an office.

- Pushing and pulling: This involves applying force to move an object away from or towards the body, such as pushing a trolley, or pulling a rope.

- Manipulating: This involves changing the position or orientation of an object without moving it from one place to another, such as turning a valve, or twisting a screwdriver.

Manual handling can be performed manually by using the hands or arms only, or by using aids or equipment such as handles, straps, levers, wheels, or cranes. Manual handling can also be performed individually by one worker, or collectively by two or more workers.

Why is Manual Handling Important?

Manual handling is important because it is essential to many jobs and tasks in different industries and sectors. Manual handling can help workers perform their work efficiently and effectively, and achieve their goals and objectives. For example, manual handling can help workers:

- Transport materials or products from one place to another

- Load or unload vehicles or containers

- Assemble or disassemble parts or components

- Install or repair equipment or machinery

- Handle patients or animals

- Perform cleaning or maintenance tasks

However, manual handling can also pose significant hazards and risks to workers’ health and safety if it is not performed correctly. Improper manual handling can cause injuries to the muscles, bones, joints, ligaments, tendons, nerves, blood vessels, or organs of the body. These injuries can range from minor cuts and bruises to serious fractures and dislocations. Improper manual handling can also cause long-term health problems such as chronic pain, inflammation, degeneration, disability, or disease. These health problems can affect not only the physical well-being of workers but also their mental and emotional well-being.

Therefore, it is important to prevent and reduce the hazards and risks of manual handling by following the legal requirements and best practices for manual handling. By doing so, you will be able to protect your workers and yourself from harm, and promote a healthy and safe working environment.

What are the Hazards and Risks of Manual Handling?

The hazards and risks of manual handling depend on various factors that affect the difficulty and complexity of the task. These factors include:

- The task: The type, frequency, duration, speed, and sequence of manual handling activities can affect the level of physical effort, stress, and strain required by workers. For example, lifting heavy objects repeatedly for a long time can be more hazardous than lifting light objects occasionally for a short time.

- The individual: The physical characteristics, capabilities, and limitations of workers can affect their ability and suitability to perform manual handling tasks. For example, age, gender, height, weight, strength, flexibility, fitness, health condition, and prior injuries can influence how workers handle loads.

- The load: The weight, size, shape, and surface of the object or material being handled can affect how easy or difficult it is to grip, lift, carry, push, pull, or manipulate it. For example, a large, heavy, bulky, or slippery load can be more hazardous than a small, light, compact, or stable load.

- The environment: The physical conditions and layout of the workplace can affect the accessibility and safety of manual handling tasks. For example, poor lighting, ventilation, temperature, humidity, noise, vibration, or space can create hazards for manual handling. Additionally, uneven, slippery, or cluttered floors, or obstacles such as stairs, doors, or furniture can increase the risk of accidents or injuries.

The hazards and risks of manual handling can result in various types of injuries or health problems, such as:

- Musculoskeletal disorders (MSDs): These are injuries or disorders that affect the muscles, bones, joints, ligaments, tendons, nerves, blood vessels, or organs of the body. MSDs can be caused by excessive or prolonged force, pressure, tension, compression, shear, torsion, or vibration applied to the body during manual handling. MSDs can affect any part of the body, but they are most common in the back, neck, shoulders, arms, hands, legs, and feet. MSDs can manifest as pain, stiffness, swelling, inflammation, bruising, bleeding, numbness, tingling, weakness, or loss of function. MSDs can be acute (occurring suddenly or immediately after manual handling) or chronic (developing gradually or persisting over time). Some examples of MSDs are:

- Back injuries: These are injuries that affect the spine or the surrounding muscles, ligaments, or discs. Back injuries can be caused by lifting heavy or awkward loads, bending or twisting the spine, maintaining poor posture, or experiencing sudden impact or jolt. Back injuries can result in lower back pain, sciatica, slipped disc, spinal fracture, or spinal cord damage.

- Sprains and strains: These are injuries that affect the ligaments (tissues that connect bones) or the muscles and tendons (tissues that connect muscles to bones). Sprains and strains can be caused by overstretching, tearing, or rupturing these tissues during manual handling. Sprains and strains can result in pain, swelling, bruising, inflammation, reduced range of motion, or loss of strength.

- Fractures and dislocations: These are injuries that affect the bones or the joints. Fractures and dislocations can be caused by breaking or displacing the bones during manual handling. Fractures and dislocations can result in pain, swelling, deformity, bleeding, nerve damage, or impaired mobility.

- Hernias: These are injuries that occur when an organ or tissue protrudes through a weak spot in the abdominal wall. Hernias can be caused by increased pressure in the abdomen during manual handling. Hernias can result in pain, bulging, discomfort, nausea, vomiting, or bowel obstruction.

- Carpal tunnel syndrome: This is a condition that affects the median nerve that runs from the forearm to the hand through a narrow passage called the carpal tunnel. Carpal tunnel syndrome can be caused by compressing or inflaming this nerve during manual handling. Carpal tunnel syndrome can result in pain

- Tendonitis: This is a condition that affects the tendons (tissues that connect muscles to bones). Tendonitis can be caused by overusing or injuring these tissues during manual handling. Tendonitis can result in pain

- Bursitis: This is a condition that affects the bursae (small fluid-filled sacs that cushion the joints). Bursitis can be caused by irritating or inflaming these sacs during manual handling. Bursitis can result in pain.

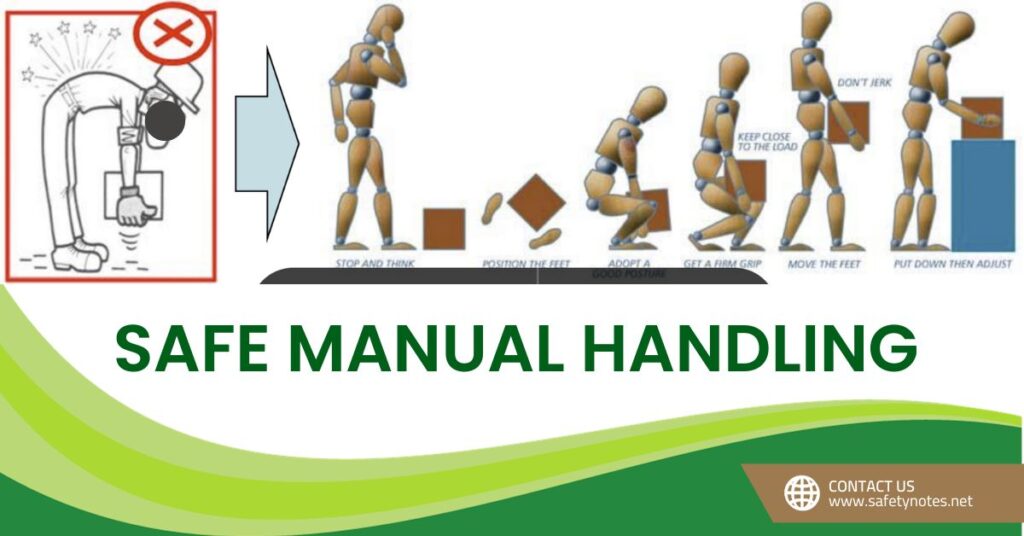

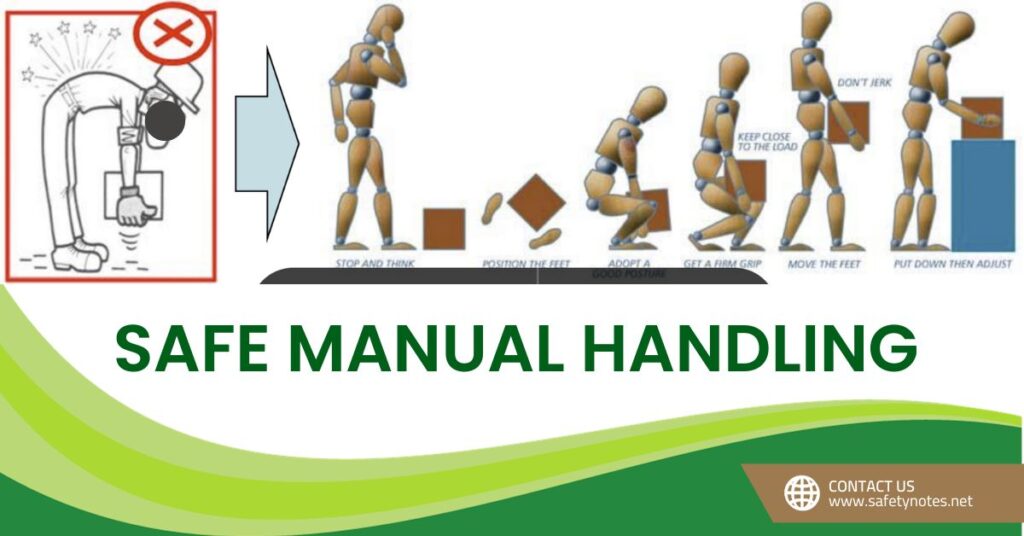

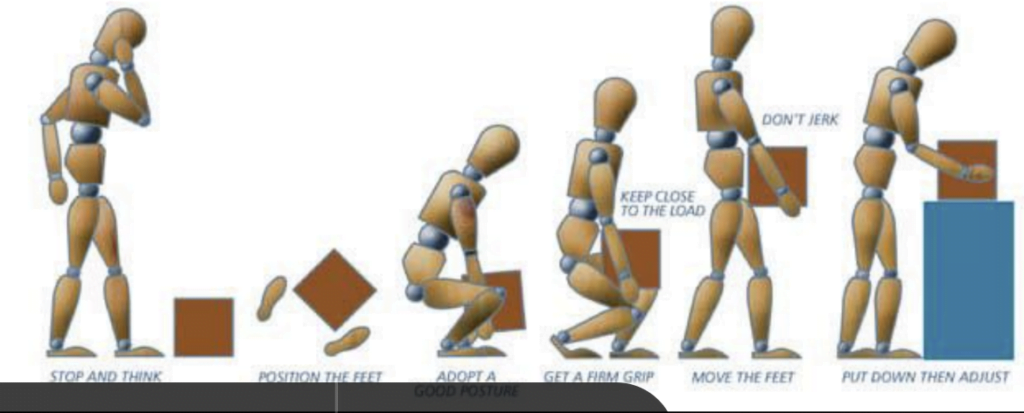

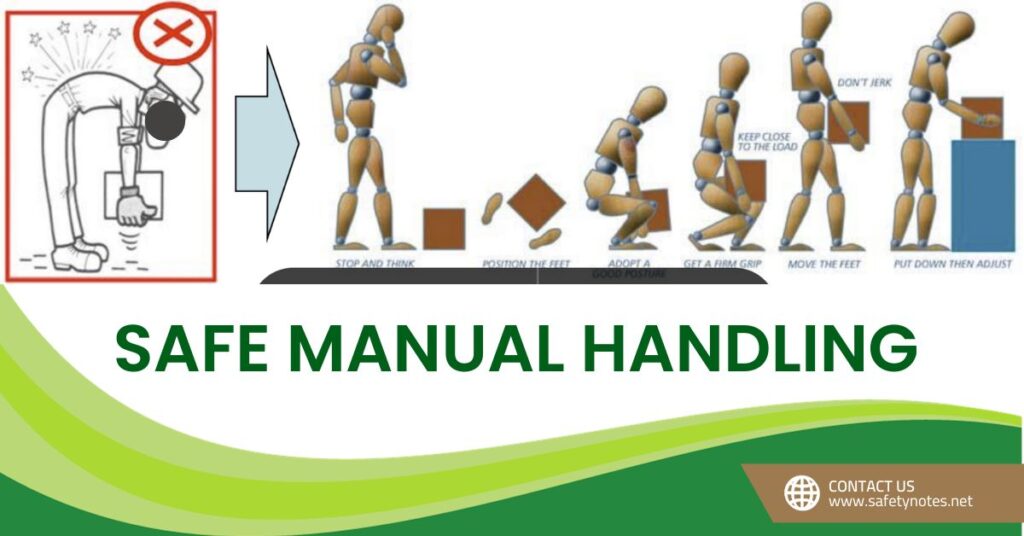

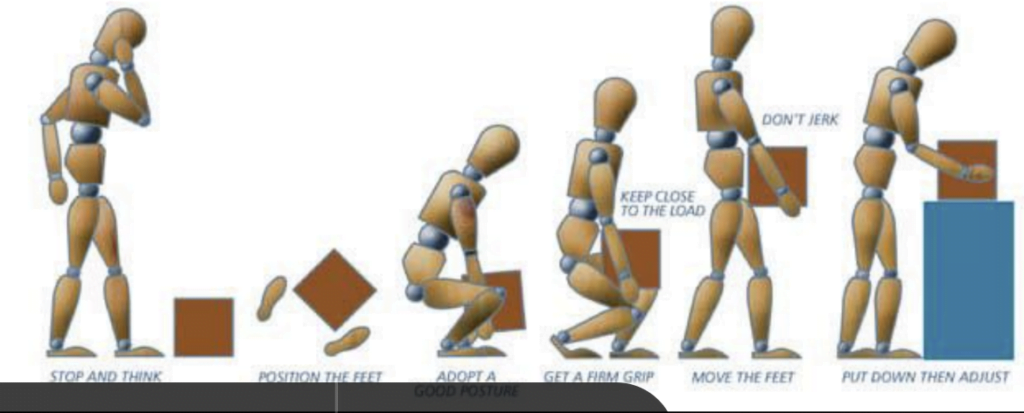

Best practices for manual handling : Safe Manual Handling

By following these best practices for manual handling, you will be able to perform your work safely and efficiently, and protect yourself and others from harm.

Safety regulations from regulatory websites on Manual handling

To prevent and reduce the hazards and risks of manual handling, you should follow the safety regulations from regulatory websites on manual handling. Here are some of the safety regulations from different sources that can help you perform your work safely and efficiently:

- The Manual Handling Operations Regulations 1992 (MHOR) are guidance designed for employers, managers and safety representatives in the UK. They explain how to avoid, assess and reduce the risk of injury from manual handling. The guidance was amended by the Health and Safety Regulations in 2002.

- The Occupational Safety and Health Administration (OSHA) is a federal agency that regulates workplace safety and health in the US. OSHA has standards and guidelines for manual handling, such as the Ergonomics Program Standard, the General Duty Clause, and the Technical Manual Chapter on Back Disorders and Injuries.

- The International Labour Organization (ILO) is a specialized agency of the United Nations that sets international standards and policies for decent work. ILO has conventions and recommendations on manual handling, such as the Occupational Safety and Health Convention, the Occupational Health Services Convention, and the Code of Practice on Safety and Health in Agriculture .

In conclusion, manual handling is a common activity in many workplaces, but it can also pose significant risks to workers’ health and safety. To prevent and reduce the hazards and risks of manual handling, you should follow the legal requirements and best practices for manual handling. You should also consult the safety regulations from regulatory websites on manual handling, such as the MHOR, OSHA, EU-OSHA, and ILO. By doing so, you will be able to protect yourself and others from harm, and perform your work safely and efficiently.